Heavy Structural Fabrication(

Home / Heavy Structural Fabrication

Heavy Structural Fabrication

At Ardee Engineering, we undertake the manufacturing and fabrication of steel components to be assembled and formed into structures.

We come with the experience of having provided structures for several industries the likes of BHEL and Gulf Oil, to name a few

We worked as the approved vendor for fabricating auto welded beams and boxes for M/s. Bharat Heavy Electricals Limited, Tiruchirapalli (Trichy), Tamil Nadu.

Here are a few of the projects that we have executed for our clientele:

- 2 sets of Bunker Shell with net weight of 426 MT (each weighing 213 MT) at new TPP Unit-2, BHEL, Neyveli.

- PEB structures with 550 Tons for M/s. PEBs Pennar, Hyderabad, Telangana.

- 230 T RDH (Rope Drum Hoist) for Medigadda, Kaleswaram project

- Feed Water Tank for Sugar Plant, 20 MT, (Dia X Length) 3600 mm X 11000 mm, with a capacity of 1,00,000 Litres for M/s. ISGEC Heavy Engineering Ltd., Noida, Uttar Pradesh.

- 130 MT of structures for Conveyor Belts for M/s. Felguera Gruas India Private Limited, Visakhapatnam, Andhra Pradesh.

- 300 MT of structures for Conveyor Belts for M/s. Bevcon Wayors Private Limited, Hyderabad, Telangana.

- Rolling works of approximately 1000 MT for M/s. Gulf Oil Corporation Limited, Hyderabad, Telangana.

- Rolling works of approximately 900 MT for M/s. Explo Weld Klad Metal Pvt Limited, Hyderabad, Telangana.

- We have contributed in the First Launch Pad –PIF Project of SDSC SAHR- ISRO at Sriharikota. We have supplied 3 No’s of Mobile Launch Pedestal (MLP’s), to First launch pad for PSLV Integration Facilities to accommodate continuous Launches from First Launch Pad. We had executed the Supply, Manufacturing, Transportation and Erection of the Mobile launch Pedestal (MLP’s). Theses MLP’s total weight of approx. (3No’s x 245 Tons). Each MLP is Fabricated in 2 Modules (Box up Model) and Other Auxiliaries of 4 No’s of Anchor Legs, 8No’s of Tapper Girders, With 1 No’s of Central Annular Structure(CAS). These Items are manufactured at Ardee Workshop Facilities and Transported to SDSCSHAR, ISRO Sriharikota for Erection and Assembly at Site of PIF Project Area. PIF Project Team visited Ardee Engineering Workshops in Hyderabad for Inspection and Control Assembly Purposes. We are Proud to Inform That ISRO-SDSC SHAR Director Visited Our Workshop and Flagged off the Movement of MLP’s (Modules) from Hyderabad to SDSC SHAR -Sriharikota And Successfully Commissioned (3 No’s) and Load Tested the entire MLP’s and witnessed by PIF Project Team Expert Committee

We at Ardee Engineering offer quality-controlled fabrication and manufacturing of steel structural components along with alignment checks and pre matching, assembly and finishing options for plating’s and coatings. Quality and safety are the two prerequisites at each of our work center’s where we provide sufficient training to improve the skills of workers and staff

Ardee Engineering is ISO 9001:2015 certified and is dedicated towards manufacturing quality fabrications to fulfill the needs of our clients. To find out more about our processes and functions, get in touch with us today!

Client List

Gallery

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: Bunker Shell 2 sets with net weight of 426 MT (Each 213 MT).

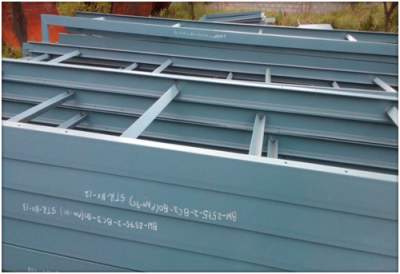

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: 1300 MT of General Structure, Auto Weld and Ducts / 1100 MT of General Structure, Auto Weld and Ducts / 1500 MT of Ducts.

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: 1300 MT of General Structure, Auto Weld and Ducts / 1100 MT of General Structure, Auto Weld and Ducts / 1500 MT of Ducts.

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: 1300 MT of General Structure, Auto Weld and Ducts / 1100 MT of General Structure, Auto Weld and Ducts / 1500 MT of Ducts.

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: 1300 MT of General Structure, Auto Weld and Ducts / 1100 MT of General Structure, Auto Weld and Ducts / 1500 MT of Ducts.

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: 1300 MT of General Structure, Auto Weld and Ducts / 1100 MT of General Structure, Auto Weld and Ducts / 1500 MT of Ducts.

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: 1300 MT of General Structure, Auto Weld and Ducts / 1100 MT of General Structure, Auto Weld and Ducts / 1500 MT of Ducts.

Location: New TPP Unit-2, BHEL - Neyveli

Specifications: 1300 MT of General Structure, Auto Weld and Ducts / 1100 MT of General Structure, Auto Weld and Ducts / 1500 MT of Ducts.

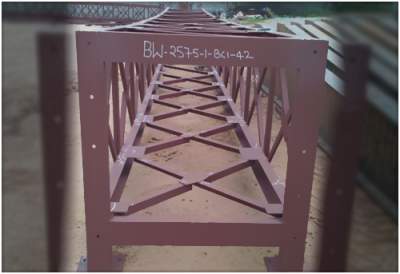

Location: Hyderabad, Telangana.

Specifications: PEB structures with 550 Tons.

Location: Hyderabad, Telangana.

Specifications: PEB structures with 550 Tons.

Location: Hyderabad, Telangana.

Specifications: 230 T RDH (Rope Drum Hoist) for Medigadda, Kaleswaram project.

Location: Hyderabad, Telangana.

Specifications: 230 T RDH (Rope Drum Hoist) for Medigadda, Kaleswaram project.

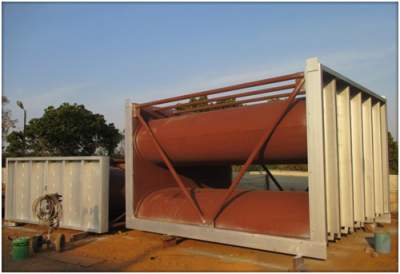

Location: Noida, Uttar Pradesh.

Specifications: Feed Water Tank for Sugar Plant, 20 MT, (Dia X Length) 3600 mm X 11000 mm, Capacity: 1,00,000 Litres.

Location: Noida, Uttar Pradesh.

Specifications: Feed Water Tank for Sugar Plant, 20 MT, (Dia X Length) 3600 mm X 11000 mm, Capacity: 1,00,000 Litres.

Location: Visakhapatnam, Andhra Pradesh.

Specifications: 130 MT of structures for Conveyor Belts.

Location: Visakhapatnam, Andhra Pradesh.

Specifications: 130 MT of structures for Conveyor Belts.

Location: Hyderabad, Telangana.

Specifications: 300 MT of structures for Conveyor Belts.

Location: Hyderabad, Telangana.

Specifications: 300 MT of structures for Conveyor Belts.

Location: Hyderabad, Telangana.

Specifications: 300 MT of structures for Conveyor Belts.

Location: Hyderabad, Telangana.

Specifications: 300 MT of structures for Conveyor Belts.

Location: Hyderabad, Telangana.

Specifications: Rolling works of approximately 1000 MT.

Location: Hyderabad, Telangana.

Specifications: Rolling works of approximately 1000 MT.

Location: Hyderabad, Telangana.

Specifications: Rolling works of approximately 900 MT.

Location: Hyderabad, Telangana.

Specifications: Rolling works of approximately 900 MT.

Door No. 8-2-334, Flat Nos: 503 & 504 Aditya Court, Road No: 5, Banjara Hills, Hyderabad - 500034, Telangana, India

info@ardee.co.in

www.ardee.co.in

040 - 23549837 & 38

040 - 23540010

Registered Office : 8-2-334/K/1, Flat Nos. 101, 102 & 103 Aditya Court, Road No. 5,

Banjara Hills, Hyderabad, Telangana, India, 500034